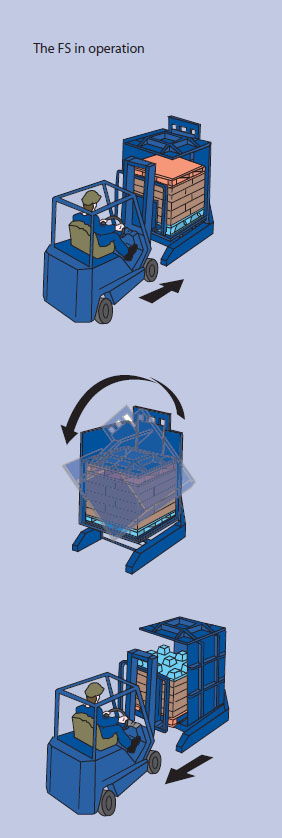

The FS Inverter is a free-standing unit designed to switch loads between one pallet and another. It is the ideal model for a wide variety of loads including boxes, bags, cans or paper regardless of the size or weight of the stack. Pallet Inverters are most commonly used to transfer product between wood and plastic pallets in food and drug production plants where hygiene is critical. The FS is also great for recovering fork-damaged goods from the bottom of the stack. One turn can save 15 minutes of manual labour.

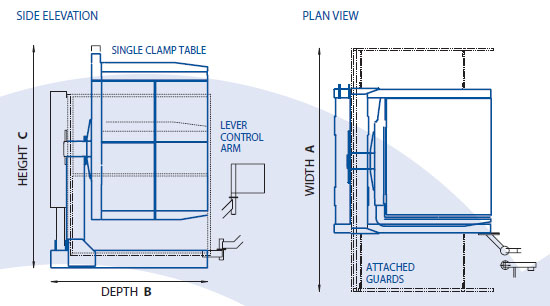

The FS Inverter adds total flexibility to your pallet control strategy and its rugged construction guarantees many years of hard wear. It is tough, reliable and well constructed but above all, simple to operate and maintain. The FS is offered in a range of standard sizes but we will also build to customers' specification. This means you can have larger jaw openings and load tables and even stainless steel bodywork. The FS Inverter is designed with a fixed table and a movable top clamp giving an opening range of 63, 75 or 86 inches.

The FS Pallet Inverter operates from a simple self-contained hydraulic powerpack that requires a basic 3 phase electrical connection. This enables the inverter to function as a stand-alone unit that can be moved to any location in the warehouse that has a suitable electric supply.

The FS Pallet Inverter is normally supplied with simple hydraulic lever controls on a short bi-fold arm. The positioning of the arm allows the user a good view of the operation from a safe standing position. The lever system is familiar to forklift truck drivers and gives a good "feel" for the machine's movement.

Clamping pressure on the product is totally variable and adjustable so there is no danger of crushing. Many operators will use the FS Inverter by simply turning the load through 90 degrees and changing the pallet while the goods are supported on the side wall. However, 180 degree inversion is more common. Loads which have to be the original way up can be re-inverted after pallet exchange.

In high-throughput situations, the FS is invariably supplied with extended push button controls on a pendant suspended from an extended arm. This enables the forklift driver to operate the inverter without leaving his cab. Semi and full automatic versions are also available as an option. Like all our other systems the FS Pallet Inverter meets the highest CE certified safety regulations.

The FS Pallet Inverter is understandably Premier's most popular model and is considered the industry-standard for this type of equipment. It has been in production for over 30 years but constant minor innovations and improvements have kept it ahead of the field.

| FS SPECIFICATIONS | ||||

| Model: | FS1600 | FS1900 | FS2200 | |

| JAW OPENING | 1.60m MAX; .92m MIN | 1.90m MAX; 1.06m MIN | 2.20m MAX; 1.13m MIN | |

| STD LOAD TABLES | 1.37m x 1.22m | 1.37m x 1.22m | 1.37m x 1.22m | |

| LOADING CAPACITY | 2000 kgs | 2000 kgs | 2000 kgs | |

| POWER SUPPLY | 3ph/400V/15A | 3ph/400V/15A | 3ph/400V/20A | |

| MOTOR SIZE | 2.2kw | 3kw | 4kw | |

| WEIGHT | 1700 kgs | 1850 kgs | 2000 kgs | |

| WEIGHT OF GUARDS | 175 kgs | 175 kgs | 175 kgs | |

| Smaller or larger models can be custom-built | ||||

| Controls | All models fitted with dual hydraulic lever controls as standard. Extended individual push button controls or computerized auto-sequenced systems available as option. | |||

| OPERATING SPACE | 2.80m WIDE X | 2.80m WIDE X | 3.31m WIDE X | |

| INCL. ATTACHED | 2.10m DEEP X | 2.10m DEEP X | 2.10m DEEP X | |

| GUARDS | 2.56m HIGH | 2.73m HIGH | 3.61m HIGH | |

| Depth increases to 3.30m on all machines when fitted with floor fixed guards and multi photo-beams. | ||||

| STANDARD SHIPPING | 2.80m WIDE X | 2.80m WIDE X | 3.31m WIDE X | |

| DIMENSIONS WITH | 2.10m DEEP X | 2.10m DEEP X | 2.10m DEEP X | |

| GUARDS FITTED | 2.20m HIGH | 2.30m HIGH | 2.40m HIGH | |